Summary and Features

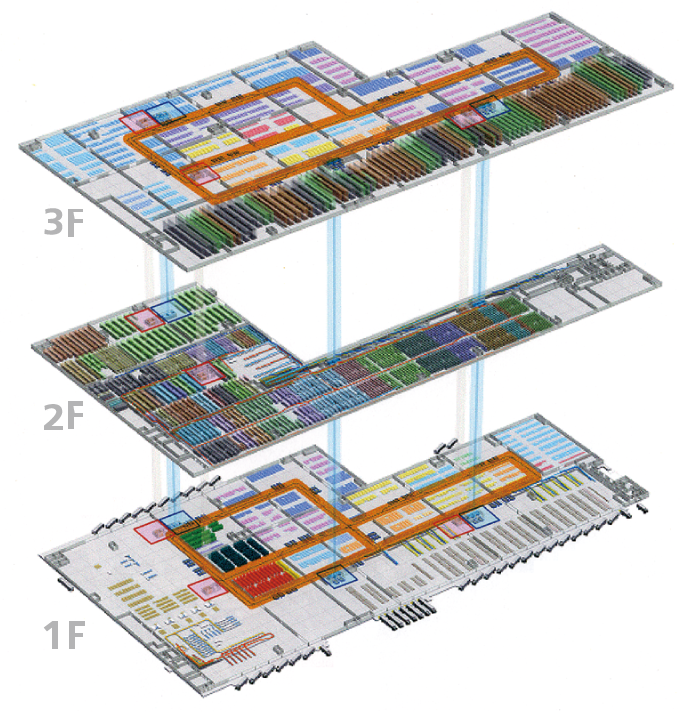

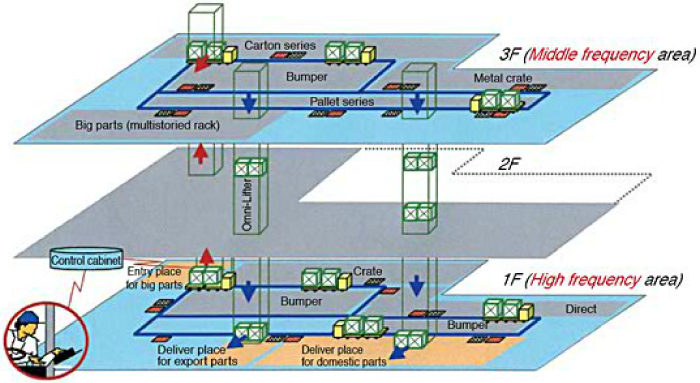

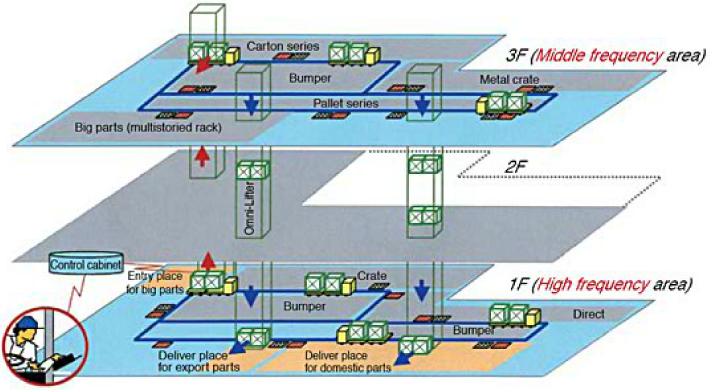

A combination of Omni Lifters and Automatic Guided Vehicles (AGVs) helps eliminate the need for manned forklifts, and help streamline the operation of 3-story distribution centers. Auto parts entering and leaving the facility include everything from large sheet metal fabrications (weighing 500-1000 kg each) to mid-size and small parts, and these can be sorted by floor depending on shipping frequency. Instructions for incoming and outgoing goods are all computer controlled to ensure a highly reliable flow of goods within the distribution center.

Transport of large parts

Products are transferred to every station in an area by AGV on 1F.

Products are transferred to every station in an area combining with Omni-Lifter and AGV on 3F.

3F (Middle frequency area)

- Connection points with Omni Lifter : 3 places

- AGV loading : 8 places

- AGV unloading : 9 places

1F (High frequency area)

- Connection points with Omni Lifter : 3 places

- AGV loading : 9 places

- AGV unloading : 8 places

- Both loading and unloading : 1 place

Main Devices

-

Collection conveyor linked with unmanned transport cars (3F) -

Transfer status from unmanned transport car to conveyor during the shipping process -

Station conveyor

(Cargo weight per piece: 1,000 kg) -

Station conveyor -

Transport conveyor on 1F -

Specifications

【Omni Lifter】

| Type | Units 1 and 2 3RZC-H-7-10 Units 3, 4, 5, and 6 2RZC-H-6-10 |

|---|---|

| Activation System | Full automatic / manual / pushbutton, changeable |

| Control System | Elevation control, inverter control |

| Elevation Speed | 40m/min |

| Elevation Drive | 7.5kW Inverter control |

| Lateral Speed | 12m/min 24m/min |

| Lateral Drive Power | 0.4kW Inverter control |

| Conveyance System | Independent block, zigzagged chain drive, roller conveyor |

| Roller Spec | Escalation table 114.3φ×1,200w×127.0P×2rows Loading section 114.3φ×1,200w×127.0P×2rows |

| Loading Direction | Front loading |

| Loading Method | Conveyor line connection and forklift |

| Power Supply | 3φ 220W 60Hz 11.5kW/1unit |

| Other | Safety fence, mounted in a loader. fork stopper, collection with unmanned transport car, optical communication equipment |

(Unit: mm)

【Station Conveyor】

| Type | Chain driven roller conveyor |

|---|---|

| Roller Spec | 114.3φ×1,200W×127.0P×2rows |

| Bearing | Independent pillow block system |

| Chain Drive System | Two-roller zigzagged drive system |

| Dimensions (WxLxH) | 2,600W×3,250L×550H |

| Speed | Horizontal travel : 12m/min |

| Electric Motor | 0.40kW GM×2 |

| Frame | Steel plate bending bolt fixing system |

| Guide | Center: floating guide, both sides: fixed guide |

| ACV Collection | Optical communication equipment |

(Unit: mm)