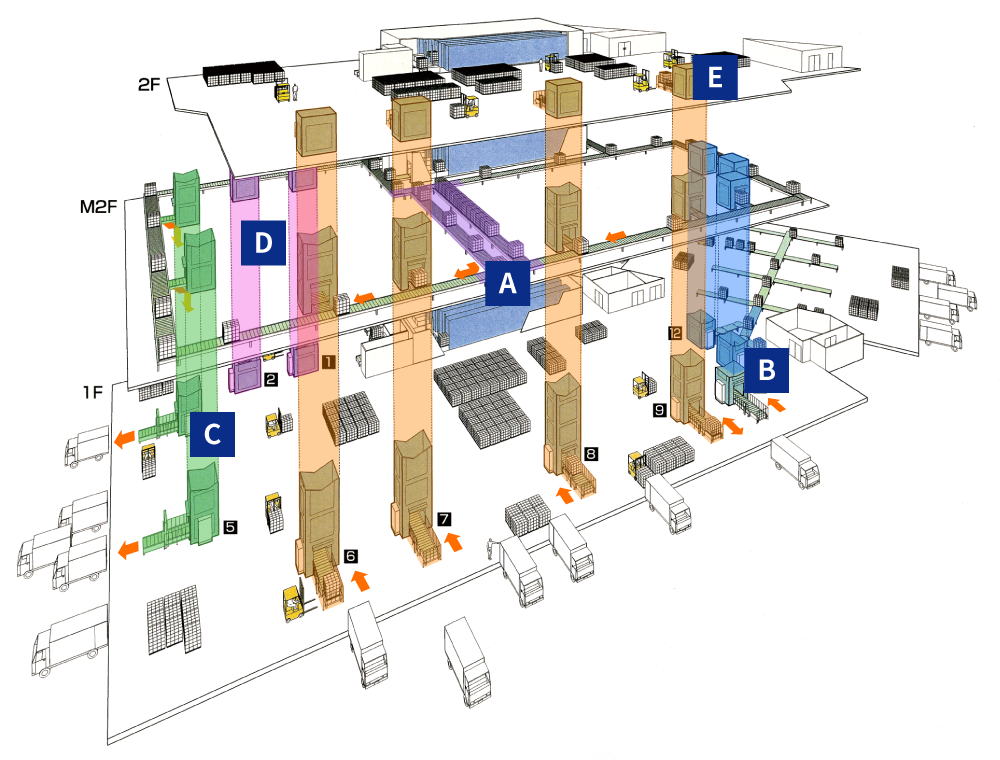

Summary and Features

Functionally controlling 12 Omni Lifters and 250 round conveyors on the mezzanine level dramatically reduces ground-floor sideline-waiting, increases goods handling space, and helps reduce cart-contact accidents. This can also link with refrigerated spaces and smooth the flow of products within the market almost limitlessly.

1, 2, 6, 7, 8, and 10 are for deliveries in; 3, 4, 5, 11, and 12 are for deliveries out; 9 is can be used alternately for either.

-

A

“Short-cut line”is installed in an endless conveyor line. Easy to be combined to delivery gate.

Change in direction of pallet on the conveyor will be done by chain up-down device.

-

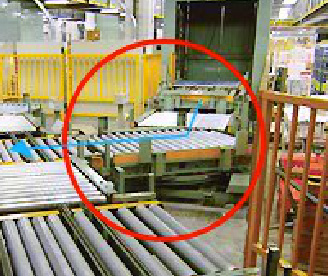

B

Products from two Omni Lifters are flowed in one way by direction exchanger.

(A conveyor in a ○ mark turns around and products from Omni Lifter go into conveyor line.)

-

C

1F floor is full of goods.

Traverse motion cannot be done.

First every goods are fed to M2F by Omni Lifter.

You can see No.9 & No.10 Omni Lifter and conveyor lines in M2F. -

D

1F No.1, No.2 feeding conveyor

Products are fed from 1F to M2F.

-

E

Omni Lifter installed on 2F《Units 6, 7, 8 and 9》

Products are delivered going-down through slope.