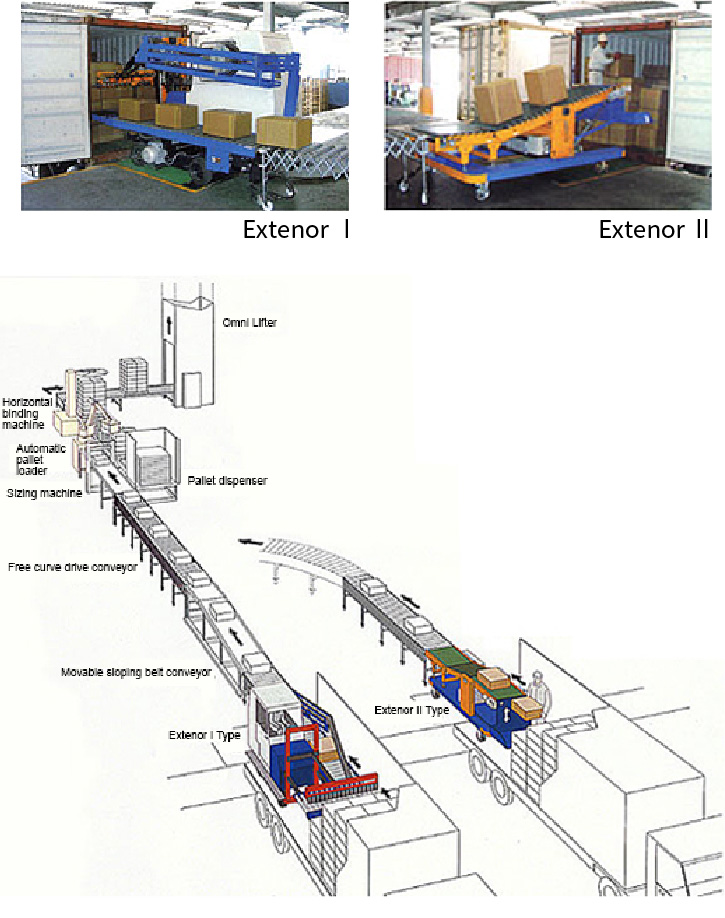

Summary and Features

A robot device that uses a suction pad to carry out a cardboard packing case.

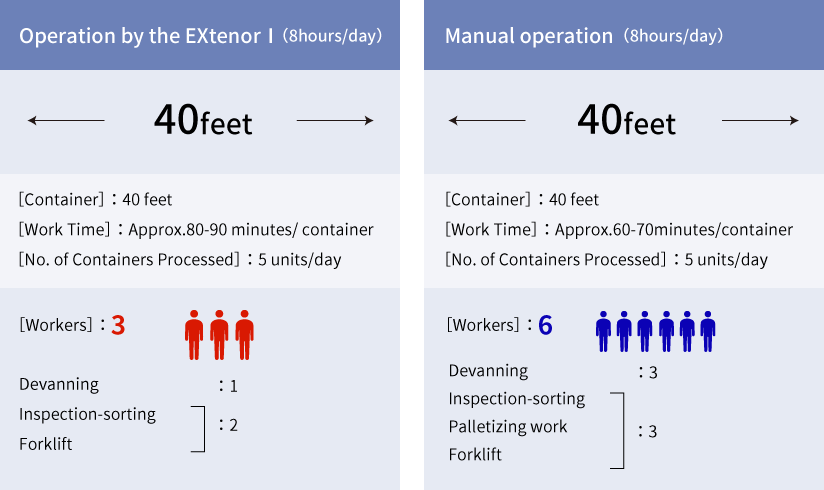

Robotic Movement (half-automatic, single-operator)

Using an adhesion pad, this robot-ized system carries corrugated cartons stacked in the container from back front.

Operable by all kinds of workers

So easy to use, the Extenor makes it possible to do the formerly labor-intensive work of unloading with just a single worker (and makes the work easier for those with less physical strength or stamina).

Let’s solve the devanning problem

Difficult Manual Labor Working Environments

Working inside a cargo container can be arduous, especially in the summer when temperatures inside can exceed 50°C.

It is difficult, dangerous hard work, making it difficult to retain good workers (or find replacements), and aging workforces only exacerbate the problem.

Risk of Injury

Many areas inside cargo containers are high-up and hard to reach, forcing workers into dangerous situations such as standing on top of cargo or underneath potentially falling cargo. Such situations increase the possibility of injury, and lead also to product damage.

Product Damage

In the container vanning and devanning industry, it has become a pressing problem to find new, more efficient methods that protect worker safety while also eliminating losses incurred when products are damaged or dirtied.

EXTENOR solve these devanning challenges.

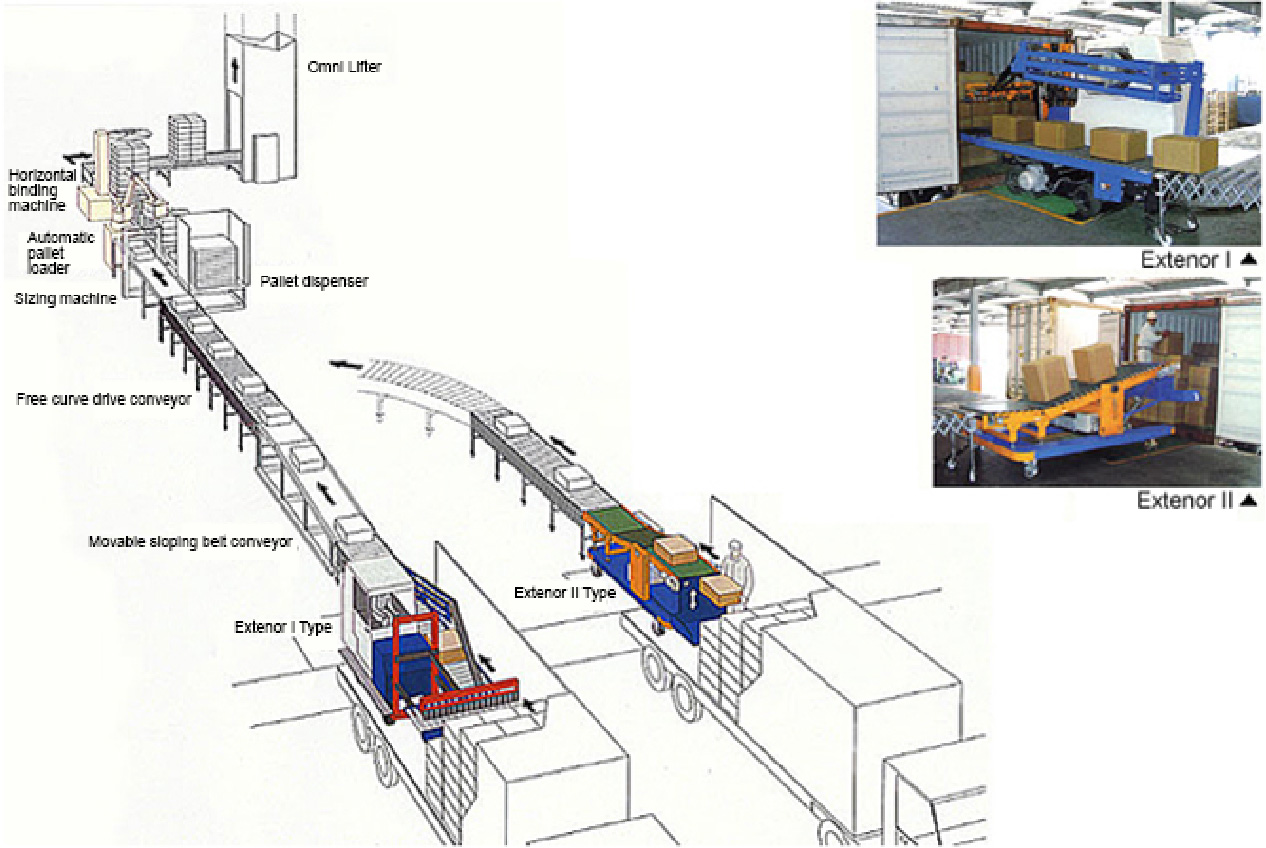

Examples of Application

Specifications and Drawings

| Robotic Movement | Semi-auto, single operator (even with less strength) |

|---|---|

| Containers | 20-foot and 40-foot |

| Applicable Goods | Cartons, cardboard boxes, products in cases |

| Operator Seat | Air conditioned |

| Cargo Loading Method | Vacuum type. Conveys starting with upper part of stacked cargos in 1-row units using 20 pads per row. |

| Unloading Method | Carriage by roller conveyor |

| Load Weight | Max. 20kg/case (8kg/pad total unloading weight:) |

| Cargo Dimensions | MIN200W×200L×200H〜MAX800W×800L×800H |

| Unloading Capacity | 900 pieces/hour (max. at straight stack) (interlocked stack possible) |

| Chassis | DC motor with onboard battery |

| Maximum Level Speed | 5km/hour |

| Operating Time | 5 hours, continuous |

| Vacuum Generator | Blower type (6.3kW output) |

| Unloading Power Supply | 200V 50/60Hz 18.2kW |

* Specifications are subject to change without notice.