Summary and Features

A dedicated pallet circulation type vertical conveyor that achieves high capacity and space saving for loading and unloading.

A space-saving pallet-circulating vertical conveyor!

The OMNI LIFTER Σ Type is designed to help move goods in and out with a minimum footprint, ideal for keeping aisles open in narrow warehouses.

Since it’s no longer subject to costly inspections, it helps reduce running costs while offering all the same features as the PL Type.

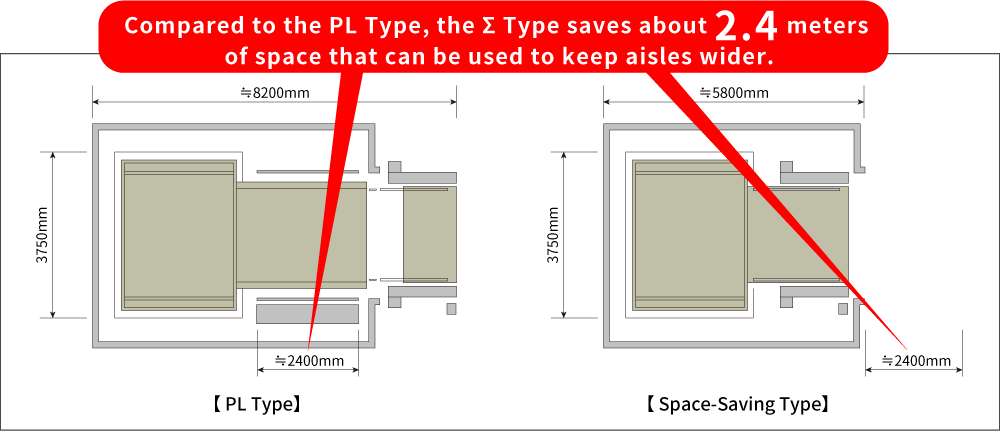

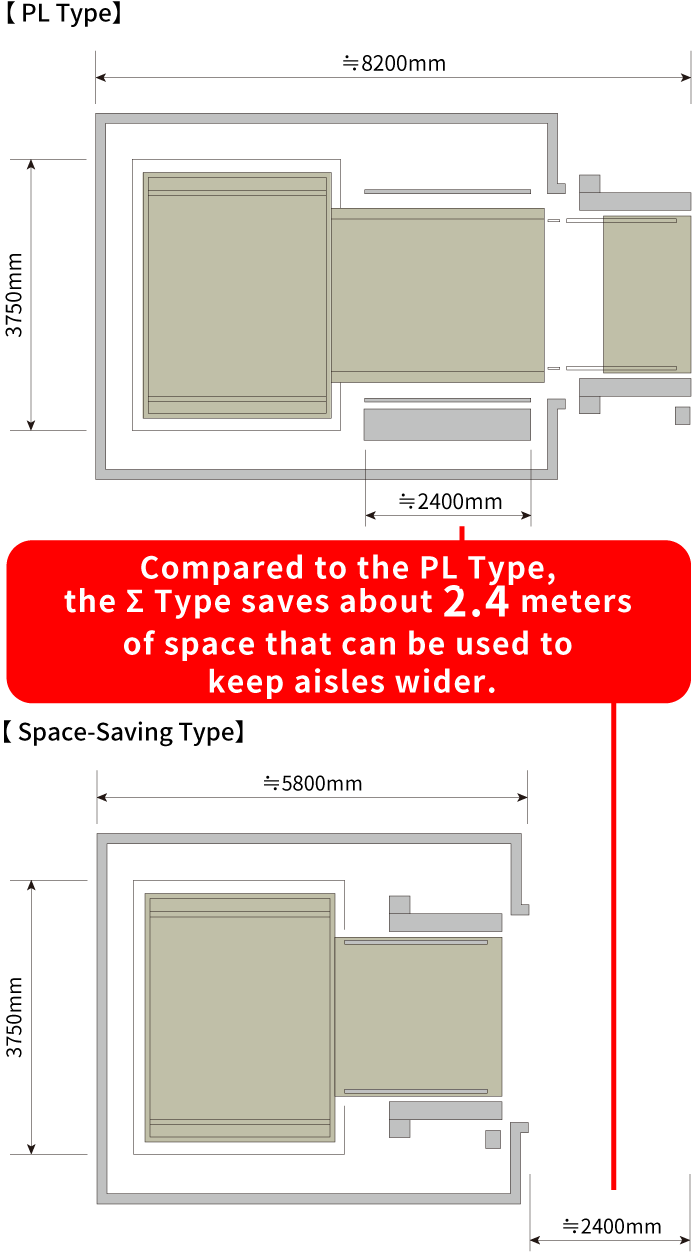

Space-saving design

Occupies about 40% less space than similar loading systems.

Reduces running costs

Instead of the normal twelve annual inspections to which elevators are normally subject, the Omni Lifter Σ Type needs only four voluntary self-inspections a year, cutting running costs dramatically.

No construction permit required

Unlike elevators, installation of the OMNI LIFTER Σ Type does not require application for a construction permit.

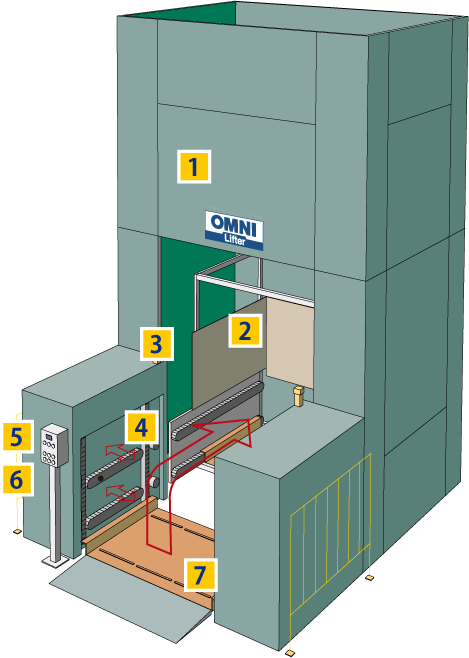

Main Devices

1. Vertical conveyor passage

2. Lifting/lowering table

3. Cargo height sensor

4. Special pallet lifter

5. Operator panel

6. Load/discharge conveyor

7. Special pallet

Cases

Installation Dimension

Specifications and Drawings

| Model | 3PE-H-3-10-Σ |

|---|---|

| Max. Cargo Weight | 1,000kg |

| Cargo Dimensions | 1,700W×1,300L×2,000H (including pallet) |

| Rolling Pallet Cart Dimensions |

800W×1,100L×1,800H (2 each, side-by-side) |

| Pallet Dimensions | 1,500W×1,200L |

| Special Pallet Dimensions | 1,800W×1,600L |

| Table Dimensions | 2,200W×2,000L (usable portion) |

| Conveyance Speed | 60m/min (inverter-controlled) |

| Lift/Lower Power | 11kW |

| Lateral Speed | 24m/min |

| Lateral Power | 1.5kW×2 |

| Loading Mechanisms | 1 per floor, 3 total |

| Loading Method | Forklifts, manual push |

| Loading Orientation | From front |

| Conveyance Capabilities | 1F-2F:70 Pt/hour; 1F-3F:40 Pt/hour |

(Unit: mm)

【Additional Work Requirements】

| 1. | Run primary power supply to the Omni Lifter control panel (3φ, 200V, 50Hz, 29.6kW) |

|---|---|

| 2. | Entrance, sectioning off construction and smoke shutter installation |

| 3. | Lay concrete pad for lifter installation |

| 4. | Each floor — Loading mechanism pit construction FL-80 and perimeter corner angle embedding (L-65×65×6t) |

| 5. | 3F inspection door (800W × 1200H) installation and 3F inspection ladder installation |

| 6. | Upper conveyance passage — Install construction-use lifting beam (3 ton capacity) |

| 7. | Upper conveyance passage — Install lighting (40W) and install pressurized exhaust fan |

| 8. | 1F construction of base for main unit, pit construction, and opening of floors on each level |

| 9. | Each floor — Install wiring sleeve openings |

| 10. | Install anti-harmonic measures |

| 11. | Other —General construction related to structure, electrical, equipment and anti-disaster measures |

Special Pallet Reference Dimensions

| Width | 2,500W・2,100W・1,800W |

|---|---|

| Depth | 1,600L |

Special Pallet Dimensions, 3 patterns

| Dimensions | 2,500W× |

2,100W× |

1,800W× |

|---|

(Unit: mm)