Summary and Features

A dedicated pallet circulation type vertical carrier compatible with forklift type and trolley type (floor type).

Forklift Model

Product transporter with special pallet moves cargo with a variety of shapes and sizes

This forklift-compatible vertical conveyor allows loading and unloading directly by forklift, making it ideal for products that are difficult to palletize. Its ability to repeatedly and continuously load and unload cargos of any shape make it ideal for streamlining work efficiency.

Cart Model (Floor Model)

Raise-and-lower loading and unloading allows whole carts to be loaded in.

This lifter optimized for general-purpose use and high efficiency is ideal for warehouses loading and discharging small quantities of many different kinds of products. Loading and unloading components bring the cargo right down to floor level, so it’s easy to use with whole carts loaded with cargo.

No construction permit required

Unlike elevators, installation of the OMNI LIFTER does not require application for a construction permit.

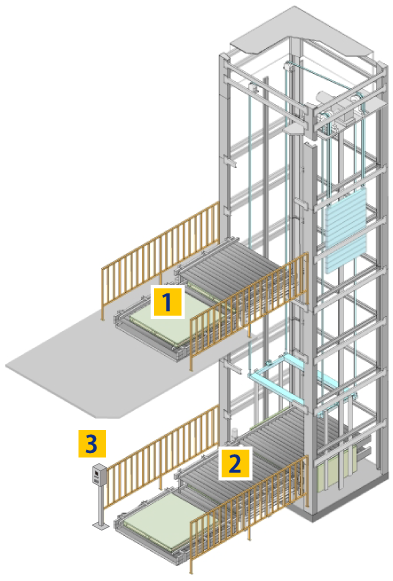

Main Devices

1. A loading and unloading device

This device checks a protrusion of the products and prevents an accident.

2. An automatic feeding device

The lifter repeats to go up and down.

Products on a pallet will be carried in and vacant pallet will be carried out.

3.Standard control box

(Touch panel)

Cases

Specifications and Drawings

| Model | 3PE-H-6-20-TL |

|---|---|

| Max. Cargo Weight | 2,000kg |

| Special Pallet Dimensions |

1,700W×1,700L (Special Pallet ) |

| Cargo Dimensions | 1,700W×1,700L×2,200H (including pallet) (Must protrude less than 100mm from special pallet edge) |

| Table Dimensions | 2,150W×2,100L |

| Conveyance Speed | 50m/min |

| Lift/Lower Power | 30kW |

| Lateral Speed | 24m/min |

| Lateral Power | 1.5(0.4)kW motor |

| Loading Mechanisms |

2 per floor (loader with table lifter) (forklift, front-loading) |

| Conveyance Capabilities |

1F-2F:86 Pt/hour; 1F-3F:65 Pt/hour (assuming load time of 10 seconds) |

(Unit: mm)

【Additional Work Requirements】

| 1. | Run primary power supply to the 3F control panel (3φ、200V、50Hz、55.0kW) |

|---|---|

| 2. | 1F – Pit construction, 16 ton capacity |

| 3. | On each floor – Opening closing construction and shaft fireproof division construction |

| 4. | On each floor – Smoke shutter installation (with open status confirmation limit switch) |

| 5. | On each floor – Construction to open floor |

| 6. | Upper part of shaft – Install internal lighting and install pressurized exhaust fan with 40°C thermocouple switch and anti-fire/anti-smoke damper |

| 7. | 3F inspection door (800W x 2000H) installation |

| 8. | Install anti-harmonic measures |

| 9. | 3F – Install 100V electrical outlets |

| 10. | Install construction-use suspension beam for upper part of shaft (3 tons capacity) |

| 11. | Each floor – Install wiring sleeve openings |